Mabry Industries, Inc. is North Carolina’s best in machining companies. Our services range from CNC machining to steel fabricating and much more. Contact us today to speak to a representative about quoting your next project.

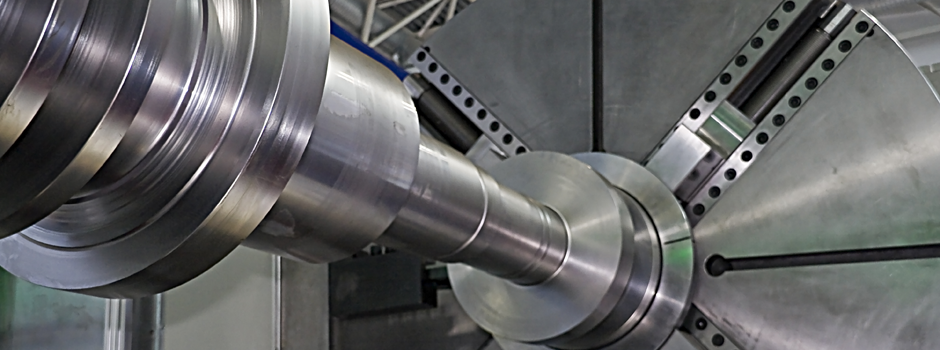

Lathes

1 — 14” X 36” CAP SOUTH BEND

1 — 16” X 48” CAP SOUTH BEND

1 — 24” X 48” CAP MONARCH

1 — 25-1/2” X 246” CAP MONARCH

1 — 21” X 96” SOUTH BEND 30” OVER GAP WITH DIGITAL READOUT

1 — 26” x 160” CAP VICTOR WITH DIGITAL READOUT

1 — 16” x 48” HAAS CNC TL-2 TURNING CENTER

Mills

1 — BRIDGEPORT SERIES I WITH POWER FEED AND DIGITAL READOUT

2 — SOUTHBEND 3 HP STANDARD MILLS

1 — CINCINNATI HORIZONTAL MILLS

1 — MILWAUKEE #2 UNIVERSAL MILL MODEL K

1 — ACER MILL WITH DIGITAL READOUT

1 — ACER MILL CNC

1 – Okuma 4VA Machining Center

Saws

1 — 10” COLD CUT SAW

1 — HYD-MECH S-20 13” X 18”

1 — HYD-MECH S-20A 13” X 18” AUTOMATIC WITH 60 DEGREE MITERING

DRILL PRESSES

6 — FLOOR MODEL DRILL PRESSES

2 — ROCKWELL FLOOR DRILLS

1 — CINCINNATI RADIAL ARM DRILL 9” X 36”

1 — AMERICAN RADIAL ARM DRILL 13” X 60

WELDERS

6 — PRODUCTION WIRE WELDERS

3 — AIRCO HELIARC

1 — ACETYLENE (HARRIS) OUTFITS

2 — LINCOLN HELIARC

3 — MILLER HILIARC

4 — ESAB Mig 4000 W/ ROBOTIC TRAC FEEDERS

FABRICATION EQUIPMENT

1 — APPOLO HYDRAULIC BENDER ½” X 5” CAP

1 — 50 TON HYDRAULIC BROACHING MACHINE

1 — 36” TIME SAVER SANDER

1 — WYSONG 100 TON 10’ PRESS BRAKE

1 — STANDARD INDUSTRIAL 325 TON 12’ PRESS BRAKE W/ CNC RAM AND BACKGUAGE

1 — WYSONG 1010 SHEAR 1/8” X 10’

1 — WYSONG 1225 SHEAR ¼” X 12’

1 — 42 TON UNI HYDRO IRON WORKER

1 — PIRANHA 50 TON IRON WORKER WITH ATTACHMENTS

1 — UNIVERSAL BENDER

1 – Krras CNC 45 Ton x 7′ Press Brake

1 — MAC-030 MEGABENDER 3” Dia. w/ 2 AXIS POSITIONER

1 — BEND-O-MATIC PIPE BENDER TO 3”

1 — UNI PUNCH 90’ NOTCHER

1 — PULLMAX NIBBLER 4’ CIRCLE

1 — KOMATSU KCR-1251 5’x10’ CNC FINE PLASMA CUTTING SYSTEM 1” MILD STEEL, ¾” STAINLESS STEEL & ALUMINUM CAPACITY

1 — KOMATSU TFP-3051 5’x10’ CNC FINE PLASMA CUTTING SYSTEM 1 ¼” MILD STEEL, ¾” STAINLESS STEEL & ALUMINUM CAPACITY

MISC. — BELT SANDERS, GRINDERS, BUFFERS

FULL SANDBLASTING NEEDS

PAINT FACILITIES

1 — 25’ X 40’ WET PAINT BOOTH W/ DRAFT AND BAKE LAMPS

1 — 15’ X 10’ X 10’ POWDER COATING BATCH SYSTEM

MISC. EQUIPMENT

1 — DAVIS KEYSEATER (STANDARD AND METRIC)

2 — TOWMOTOR LIFT TRUCKS

1 — 5 TON OVERHEAD CRANE

4 — 4 TON OVERHEAD CRANE ON TWIN BRIDGES

1 — 3 TON HOIST

3 — 1 TON HOISTS

INSPECTION EQUIPMENT

1 — MITUTOYO SPC PROCESSOR

1 — ID & OD MICROMETER TO 20”

1 — DIAL BORE GAGES TO 6”

1 — HOLE & THREAD GAGES